How the Investment Casting Process Works?

Our Step-by-Step Investment Casting Process

Investment casting involves a series of carefully controlled steps that transform a wax pattern into a durable, high-precision metal component. Here’s how we do it at Invent Cast:

Die Development

Pattern Assembly

Shelling

The wax assembly is repeatedly dipped into ceramic slurry and coated with refractory sand to form a hard outer shell.

Dewaxing

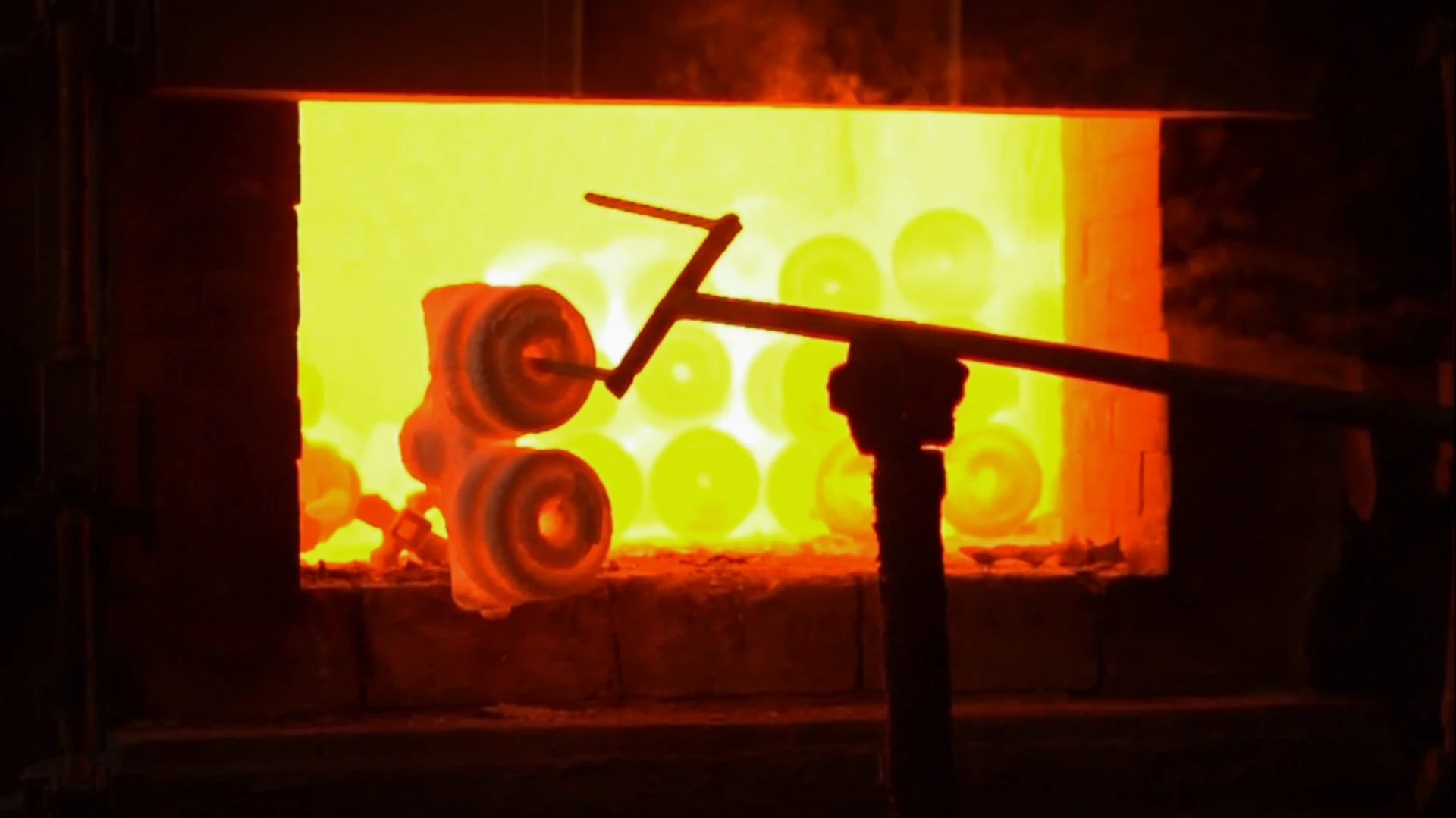

Shell Pre-heating

The shell is heated at high temperatures to increase its strength and eliminate any residual wax traces.

Metal Pouring

Heat Treatment

Heat treatment is carried out to achieve the desired micro-structure and mechanical properties.

Fettling

Casting Inspection

Machining

Final Inspection

…and what you get

Advantages of Our Process

AS Cast surface finishes as good as 3.2 Ra – 6.3 Ra, reducing machining time.

Our process controls and digital tracking ensure repeatability, especially for high-volume production.

Invent Cast delivers precision-engineered components through advanced investment casting, forging, and sand casting—serving critical industries with unmatched reliability.