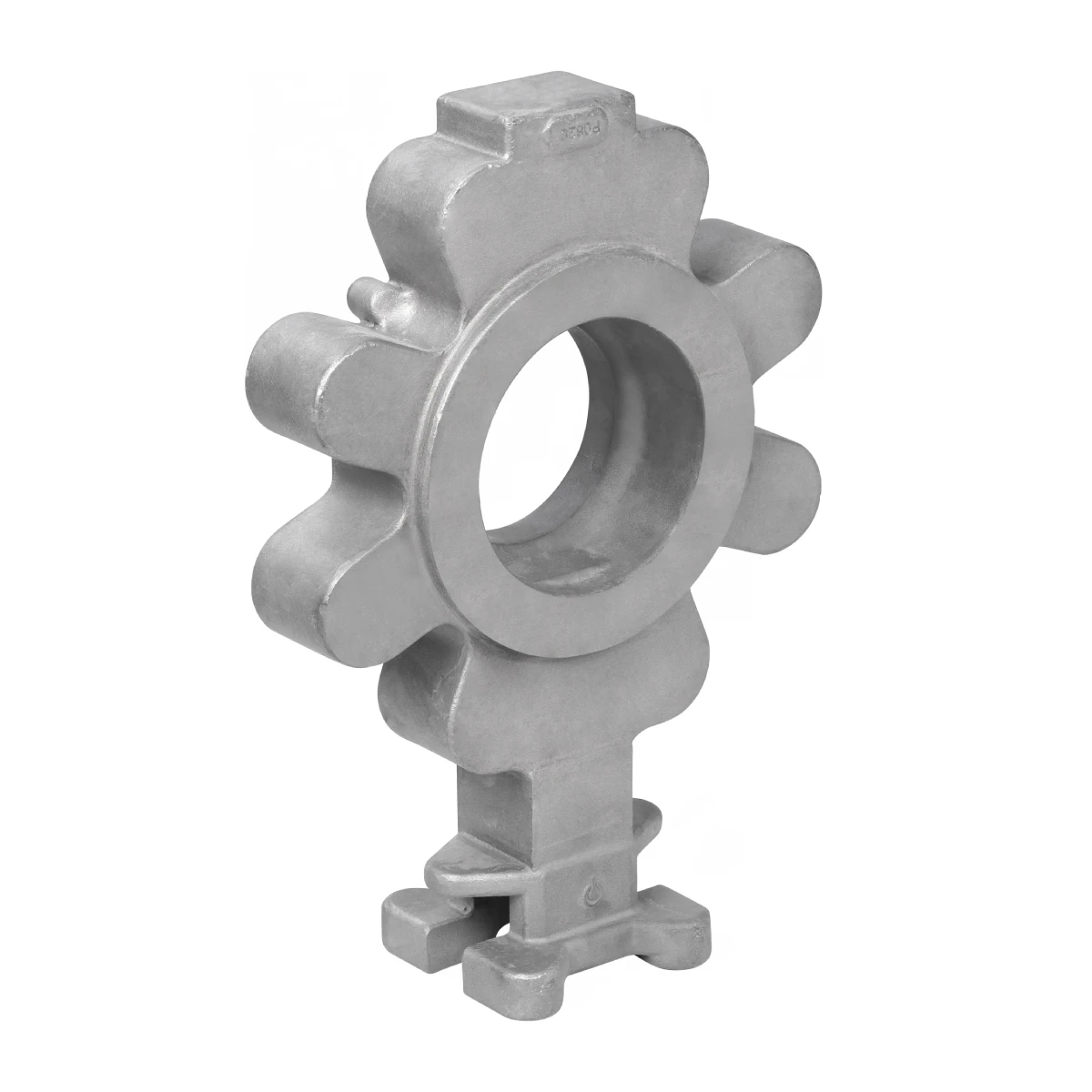

High-Precision Butterfly Valve Castings Built to Perform

At Invent Cast, we specialize in manufacturing precision investment-cast butterfly valve components engineered to global performance and safety standards. Built for lightweight strength, sealing accuracy, and smooth flow regulation — our castings ensure dependable performance in industries where efficiency and reliability are critical.

- Serving clients across the globe with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

- Serving clients across the globe with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

- Serving clients across the globe with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

Manufacturing Process

High-Precision Molding: Uniform cavity shapes for consistent quality

Controlled Pouring: Minimizes shrinkage, porosity, and turbulence defects

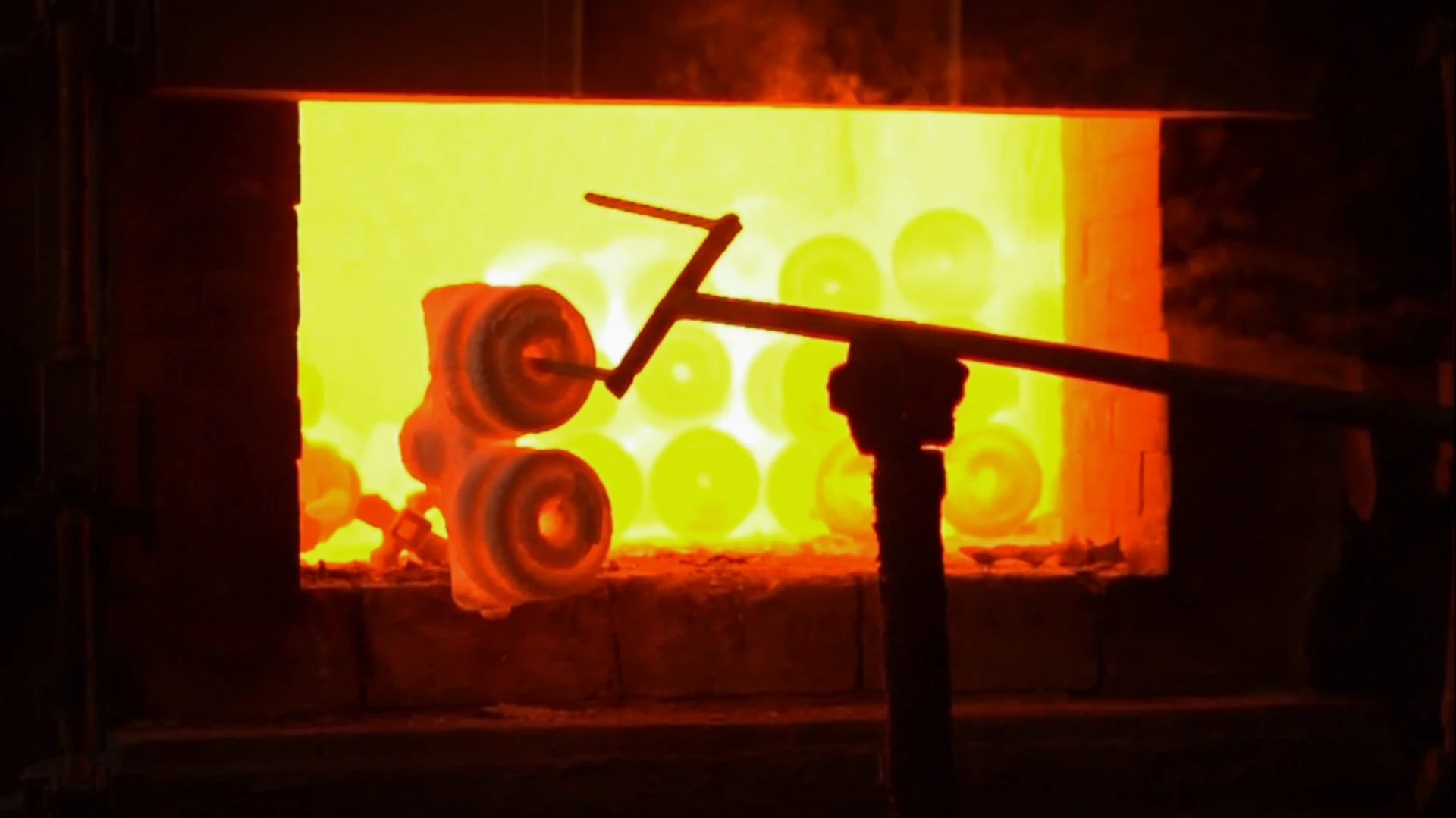

Heat Treatment: Optimizes strength, hardness, and durability

CNC Machining: Tight tolerances and smooth sealing surfaces

Final Inspection & Testing: Dimensional, visual, and functional checks for leak-proof, reliable performance

| Butterfly Valve Casting Technical Data | |

|---|---|

| R&D | |

| Lead Time for Development & Samples: 25 to 40 days | |

| Molten Metal | Stainless Steel: CF8, CF8M, Duplex, Super Duplex |

| Carbon Steel: WCB, LCB | |

| Alloys: Aluminium Alloy, Bronze, Nickel-base Alloy, Copper Alloy | |

| Metal Standard | ASTM, ASME, API, DIN, EN, BS, JIS |

| Material for Shell Building | Silica Sol (Precipitated Silica) |

| Water Glass (Sodium Silicate) | |

| Mixtures of Silica Sol and Water Glass | |

| Technical Parameter | Piece Weight: 500 g to 200 kg |

| Max Dimension: 1,200 mm for Diameter or Length | |

| Min Wall Thickness: 3 mm (depending on pressure class) | |

| Casting Roughness: Ra 3.2–6.3, Machining Roughness: Ra 1.6 | |

| Tolerance of Casting: ISO 8062 CT6–CT8 | |

| Tolerance of Machining: ISO 2768-mk / IT6 | |

| Inner Core: Ceramic Core, Urea Core, Water Soluble Wax Core | |

| Heat Treatment | Normalizing, Quenching & Tempering, Solution Annealing, Stress Relieving |

| Surface Treatment | Polishing, Sand / Shot Blasting, Electropolishing, Pickling & Passivation, Epoxy Coating, Anodizing |

| Dimension Testing | CMM, Vernier Caliper, Depth Gauge, Height Gauge, Go/No-Go Gauge, Special Fixtures |

| Chemical Inspection | Chemical Composition Analysis (20 elements), X-ray Radiographic Inspection, Cleanliness Inspection, Carbon-Sulfur Analysis |

| Physical Inspection | Mechanical Properties (Hardness, Yield Strength, Tensile Strength, Elongation), Dynamic & Static Balancing |

| Testing & Compliance | Hydrostatic Testing, Air Tightness, Set Pressure Verification, API/ISO Compliance |

| Production Capacity | Up to 150 tons/month, over 1,800 tons annually |

Testing & Compliance

We ensure every butterfly valve casting meets global quality, performance, and safety standards through rigorous testing and compliance procedures:

Dimensional Checks: CMM and gauges for precise fit

NDT Inspection: Dye Penetrant, Radiography, Ultrasonic for defect-free castings

Mechanical & Chemical Tests: Hardness, tensile strength, alloy verification

Pressure & Functional Testing: Hydrostatic, air tightness, disc rotation, torque tests

Standards Compliance: ASTM, ASME, API, DIN, EN, BS, JIS

- Serving clients across the globe with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

- Serving clients across the globe with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

- Serving clients across the globe with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼