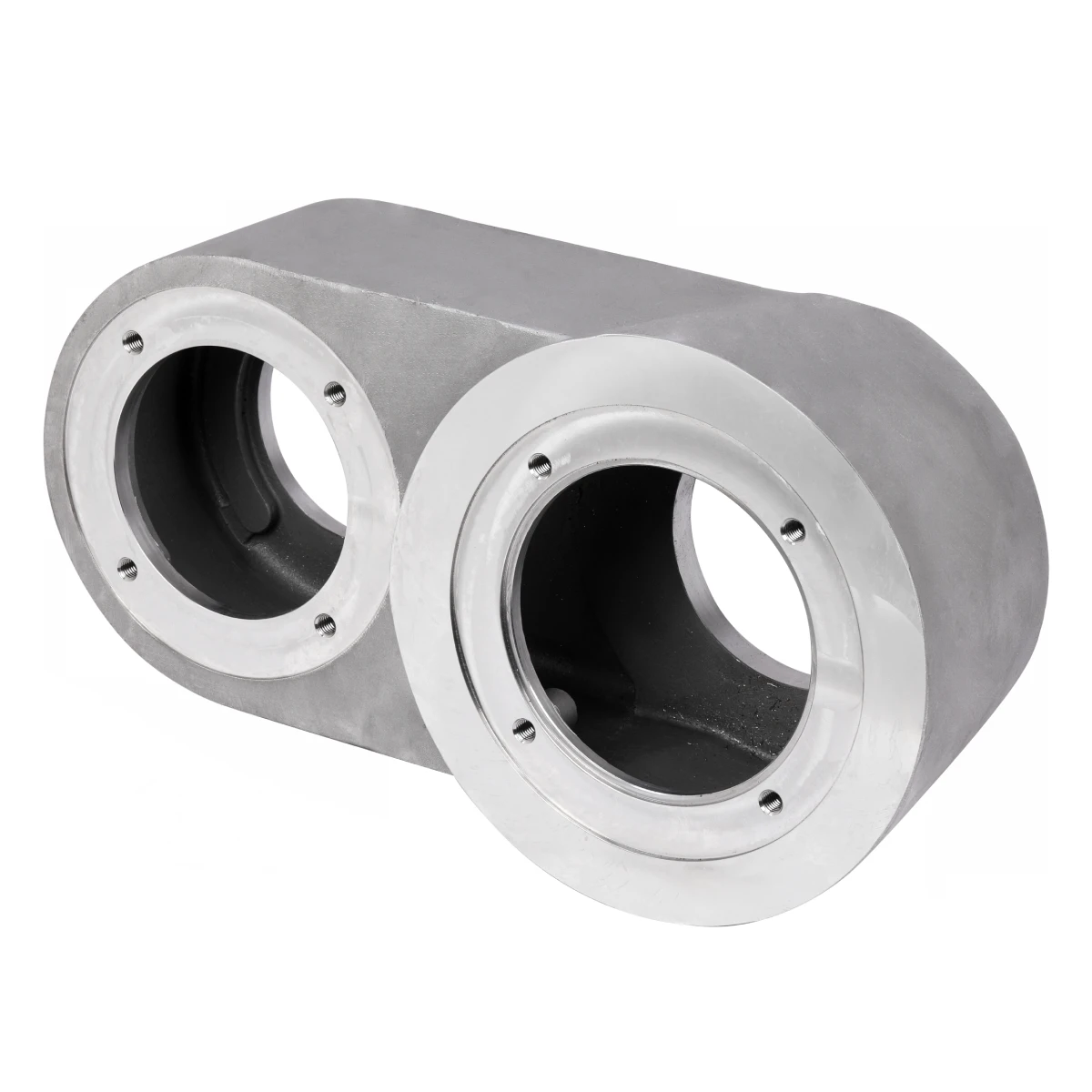

High-Precision Breather Valve Casting Built to Perform

At Invent Cast, we specialize in manufacturing precision investment-cast breather valve components engineered to meet international performance and safety standards. Designed for controlled venting, durability, and leak-proof performance — our castings ensure reliability in demanding applications where pressure regulation and protection are critical.

- Serving clients across the globe with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

- Serving clients across the globe with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

- Serving clients across the globe with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

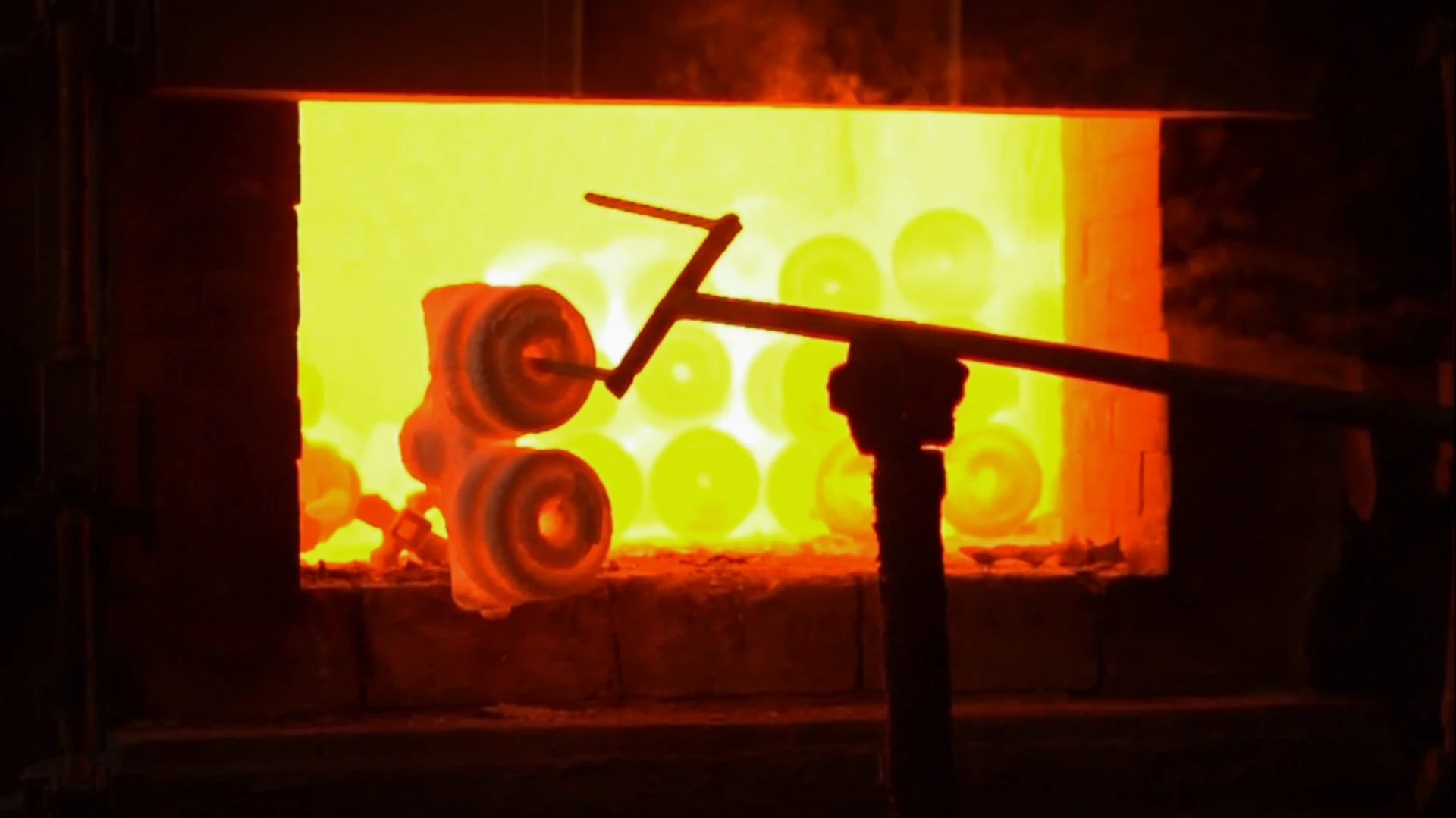

Manufacturing Process

We follow a precision-controlled casting process to ensure reliability and leak-proof performance:

Precision Molding: Accurate cavity formation for consistent quality

Controlled Pouring: Defect-free castings with minimal porosity

Heat Treatment: Optimized strength, durability, and corrosion resistance

CNC Machining: Tight tolerances and smooth sealing surfaces

Final Testing: Pressure, vacuum, and leak tests for zero-defect assurance

Testing & Compliance

We ensure every breather valve casting meets global quality and safety standards through rigorous testing and compliance checks:

Dimensional Accuracy: CMM, gauges, and precision measuring tools

Non-Destructive Testing (NDT): Dye Penetrant, Radiography, and Ultrasonic inspection for defect-free surfaces and integrity

Mechanical Testing: Hardness, tensile, yield strength, elongation, and impact resistance

Chemical Analysis: Spectro analysis to verify alloy composition

Pressure & Vacuum Testing: Compliance with API 2000 / ISO 28300 for set pressure, flow, and leak-proof performance

Surface & Finish Checks: Roughness, coating adhesion, and corrosion resistance validation

Testing & Compliance

We adhere to stringent quality protocols to ensure every ball valve casting meets international specifications:

- Hydrostatic Testing: Pressure integrity validated up to 1.5x rated pressure

- Air Leak Testing: Ensures no internal porosity or gas escape

- Dye Penetrant Testing (DP): Detects surface cracks or defects

We adhere to stringent quality protocols to ensure every ball valve casting meets international specifications:

- Hydrostatic Testing: Pressure integrity validated up to 1.5x rated pressure

- Air Leak Testing: Ensures no internal porosity or gas escape

- Dye Penetrant Testing (DP): Detects surface cracks or defects

We adhere to stringent quality protocols to ensure every ball valve casting meets international specifications:

- Hydrostatic Testing: Pressure integrity validated up to 1.5x rated pressure

- Air Leak Testing: Ensures no internal porosity or gas escape

- Dye Penetrant Testing (DP): Detects surface cracks or defects

We adhere to stringent quality protocols to ensure every ball valve casting meets international specifications:

- Hydrostatic Testing: Pressure integrity validated up to 1.5x rated pressure

- Air Leak Testing: Ensures no internal porosity or gas escape

- Dye Penetrant Testing (DP): Detects surface cracks or defects

- Serving clients across the globe with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

- Serving clients across the globe with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

- Serving clients across the globe with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼