The demand for high-quality valve components in the United States continues to grow across industries such as oil & gas, water treatment, power generation, and industrial processing. Businesses searching for valve manufacturers in the USA today are not only looking for products, but also for precision engineering, durability, and dependable global supply chains.

This is where Invent Cast stands out as a trusted international partner. As a precision investment casting manufacturer based in India with strong export capabilities to the American market, Invent Cast delivers professionally engineered valve castings designed to meet strict industrial and performance standards.

From stainless steel ball valve components to complex gate valve bodies, the future of valve manufacturing is being shaped by precision investment casting, advanced metallurgy, and global collaboration.

Understanding the Importance of Professional Valve Casting

Industrial valves operate in high-pressure, high-temperature, and corrosive environments. Even the smallest defect in casting can lead to leakage, downtime, or safety risks.

That’s why companies searching for gate valve manufacturers in the USA or reliable valve suppliers prioritise:

- Dimensional accuracy

- Metallurgical integrity

- Long service life

- Compliance with global standards

Professional valve casting ensures consistent performance across demanding applications, making it a critical foundation of modern industrial infrastructure.

Global Shift in Valve Manufacturing and Supply

Many valve companies in the United States are now partnering with international precision casting exporters to optimise production cost without compromising quality.

India has emerged as a leading destination for valve casting exporters in the USA supply chains, thanks to:

- Advanced investment casting technology

- Skilled engineering workforce

- Competitive production economics

- Strong export logistics

Manufacturers in India exporting to the USA, such as Invent Cast are enabling American industries to access premium-grade valve components at scalable volumes.

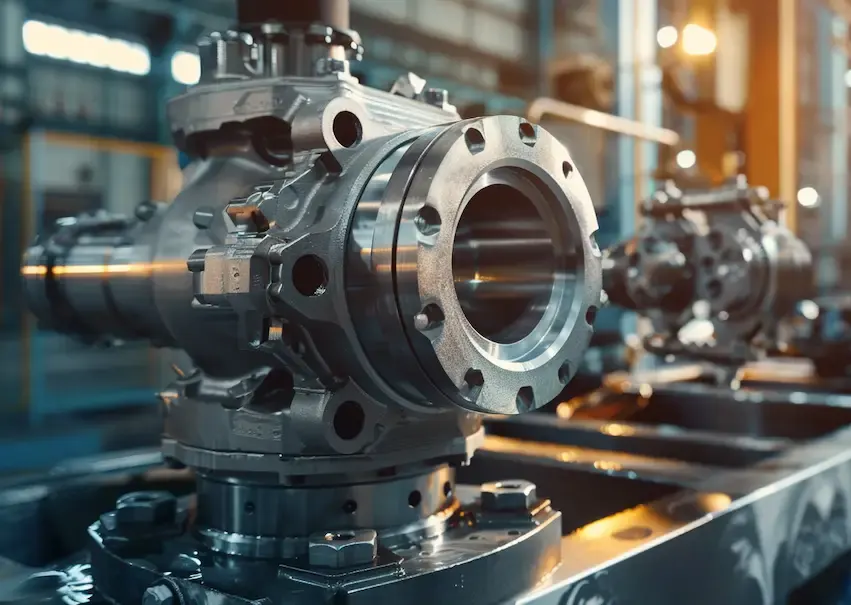

Types of Valve Castings Used Across US Industries

Professional valve casting covers a wide range of valve categories used in American industrial systems.

Gate Valve Castings

Widely used in oil pipelines and water networks, gate valve supplier requirements demand high-strength, pressure-resistant castings with flawless sealing surfaces.

Check Valve Components

Industries searching for a check valve supplier or check valve manufacturers require precision-machined internal geometries that ensure reliable one-way flow control.

Ball Valve Bodies

Modern stainless steel ball valve systems depend on corrosion-resistant investment cast housings for long-term durability in chemical and marine environments.

Hydraulic Valve Castings

Heavy machinery and automation sectors rely on hydraulic valve suppliers capable of delivering tight-tolerance castings for fluid power control.

Each of these applications highlights why professional casting quality directly impacts operational reliability.

Why Precision Investment Casting Is Preferred for Valve Manufacturing

Investment casting also known as lost wax casting, has become the preferred process for high-performance valve components.

Key Advantages

- Exceptional dimensional accuracy

- Smooth internal flow surfaces

- Reduced machining requirements

- Complex geometry capability

- High material strength

These benefits make investment casting ideal for valve casing in USA industrial systems, where performance and safety cannot be compromised.

Role of Stainless Steel in Modern Valve Castings

Corrosion resistance is essential in chemical, marine, and water treatment applications.

That is why stainless steel investment casting is widely used in:

- Stainless steel ball valve assemblies

- High-temperature processing valves

- Sanitary and pharmaceutical systems

Professional casting ensures uniform grain structure, pressure integrity, and long-term durability, meeting the expectations of demanding American industries.

Invent Cast: Trusted Export Partner for the USA Valve Industry

Among global suppliers, Invent Cast has earned recognition for delivering precision valve casting solutions aligned with US industrial requirements.

Core Strengths

- Advanced investment casting manufacturing

- High-quality stainless steel castings

- Customised OEM valve casting development

- Reliable export capability to the USA

As a valve casting supplier in the USA supply chains, Invent Cast supports valve manufacturers, distributors, and engineering companies seeking dependable global sourcing.

Quality Standards That Matter to American Buyers

US industries expect strict adherence to international material and testing standards.

Professional casting exporters must ensure:

- Chemical composition verification

- Mechanical strength testing

- Non-destructive inspection

- Pressure integrity validation

Invent Cast follows process-driven quality control systems, ensuring every exported valve casting meets industrial reliability expectations.

Choosing the Right Valve Casting Supplier

Businesses searching online for valve companies near me or evaluating valve manufacturers globally should assess:

- Engineering Capability

Ability to produce complex valve geometries with precision.

- Material Expertise

Experience with carbon steel, stainless steel, and alloy grades.

- Export Reliability

Proven track record as a manufacturer in India exporting to the USA.

- Custom OEM Support

Capability to develop application-specific valve casting solutions.

Selecting the right partner ensures long-term operational success, not just short-term procurement.

Applications Driving Valve Casting Demand in the USA

Professional valve casting plays a critical role across multiple American industries:

- Oil & Gas pipelines

- Water distribution infrastructure

- Chemical processing plants

- Power generation facilities

- Industrial automation systems

Each sector depends on high-precision valve casing for USA industrial performance, reinforcing the need for trusted global casting suppliers.

Internal Expertise and Scalable Manufacturing at Invent Cast

Beyond standard production, Invent Cast offers:

- Custom gate valve casting development

- Precision check valve body manufacturing

- Durable hydraulic valve casting solutions

- High-volume OEM valve casting supply

This combination of engineering expertise and scalable manufacturing positions Invent Cast as a reliable partner for American valve companies.

Future of Valve Casting in the United States

The US valve industry is moving toward:

- Higher efficiency flow systems

- Corrosion-resistant materials

- Smart industrial automation

- Globalised supply chains

Professional casting exporters who combine precision, reliability, and cost efficiency will define the next generation of industrial valve manufacturing.

Partnering for Professional Valve Casting Excellence

As demand grows for professional valve casting in USA, industries are increasingly collaborating with trusted global precision casting manufacturers.

With advanced investment casting technology, high-quality stainless steel valve components, and proven export capability to the American market, Invent Cast delivers the reliability, performance, and engineering precision modern industries require.

For businesses seeking:

- Dependable valve casting suppliers in the USA supply chains

- Custom OEM valve casting solutions

- High-performance stainless steel and alloy valve components

Invent Cast stands ready to support your next project with precision, quality, and global manufacturing excellence.

👉 Contact Invent Cast today to discuss your valve casting requirements for the USA market.