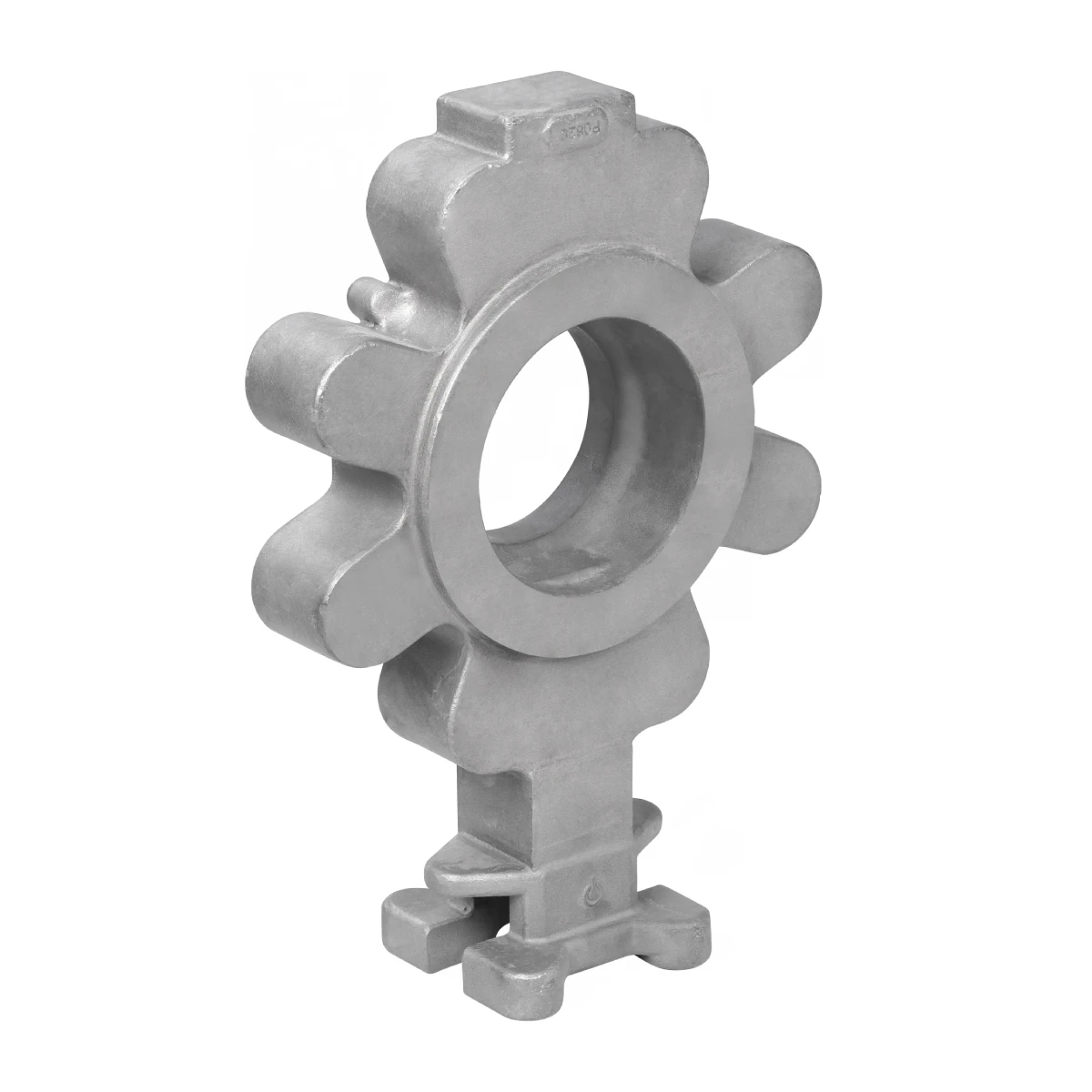

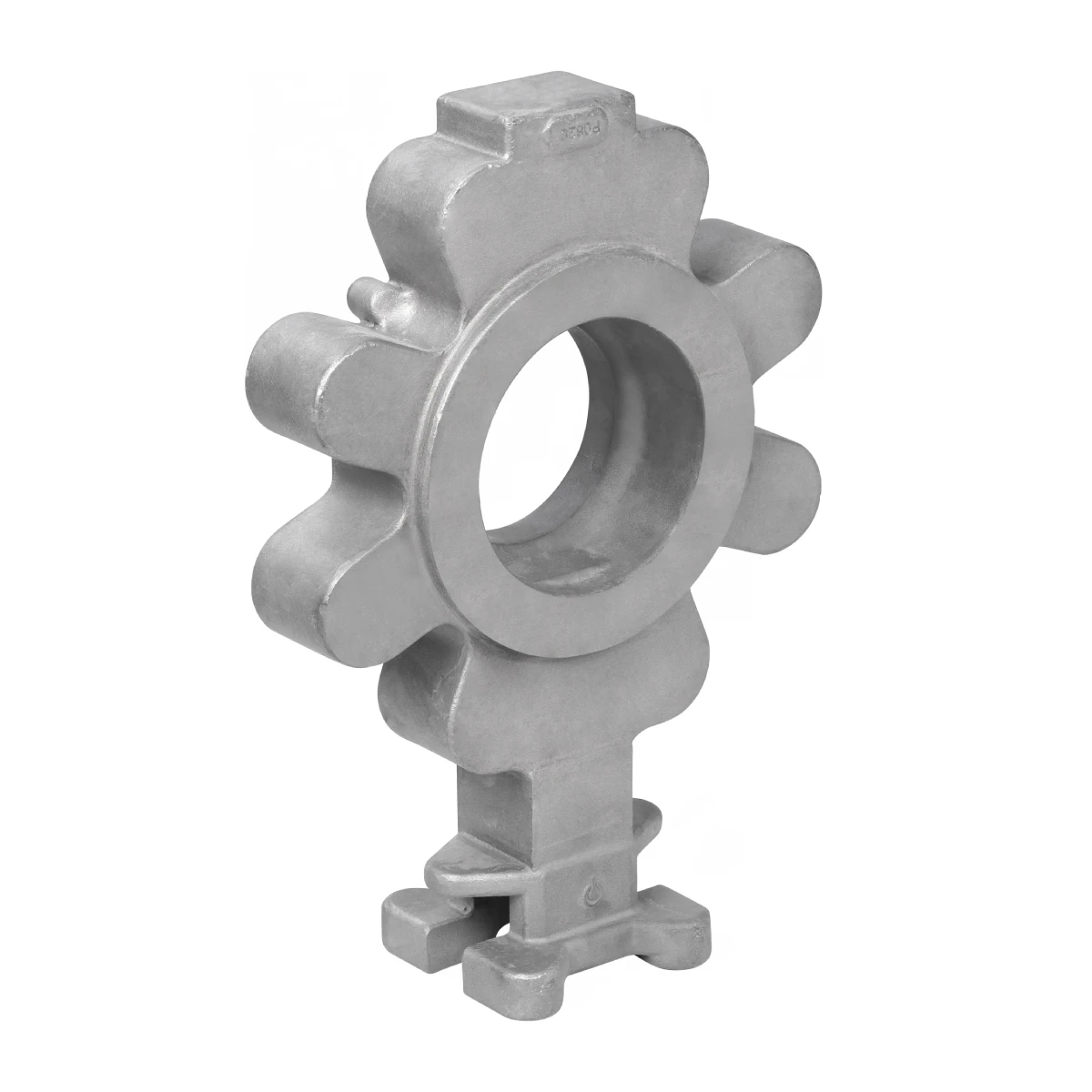

Investment Casting for Valves Industry

At Invent Cast, we specialize in high-precision investment castings tailored for the valve industry. From valve bodies to intricate trim parts, we manufacture components built to handle high pressure, corrosion, and demanding flow environments.

- Serving clients across the globe with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

- Serving clients across the globe with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

- Serving clients across the globe with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

Why Investment Casting is an Ideal Process for Valve Parts?

Valves demand dimensional accuracy, leak-proof sealing, and material strength — all of which are achieved through investment casting. The process allows for:

- Smooth internal flow paths for improved fluid dynamics

- Consistent wall thickness to prevent stress concentrations

- Corrosion-resistant materials ideal for water, chemicals, or gas environments

- Leak-free performance through tight dimensional tolerances

- Cost-effective production with reduced machining and post-processing

These benefits make investment casting the preferred choice for valves manufacturers across critical industries.

Why Choose Investment Casting with Invent Cast?

Our casting process has been fine-tuned over years of experience. Clients choose us because:

- Tight Tolerances: Critical dimensions are maintained to meet demanding applications

- Excellent Surface Finish: Minimal machining is needed post-casting

- Versatile Materials: From stainless steel to high-grade alloys

- Cost Efficiency: Especially for medium-to-high volume production

We also provide in-house tooling design, machining, and heat treatment — ensuring full control from concept to final part.

Explore our Valve Casting Components

Ball Valve Casting

Breather Valve Casting

Butterfly Valve Casting

Check Valve Castings

Gate Valve Casting

Safety Valve Casting

Slurry Valve Castings

Wafer Type Non Return Valve Castings

Fire Safety Valve Castings

Technical Capabilities

We offer a wide range of manufacturing capabilities to support diverse valve applications:

- Materials: Stainless steel, duplex steel, super alloys, Hastelloy, etc.

- Casting Weight: 50g to 50kg

- Surface Finish: Up to 3.2 Ra without machining

- Machining: CNC, turning, drilling, threading available in-house

- Tolerances: As per ISO 8062, up to ±0.1mm

- Testing: Hydro pressure test, air leak test, dye penetrant test

- Certifications: Compliant with ASTM, API, EN, and DIN standards

Custom packaging and material traceability are provided for every order.

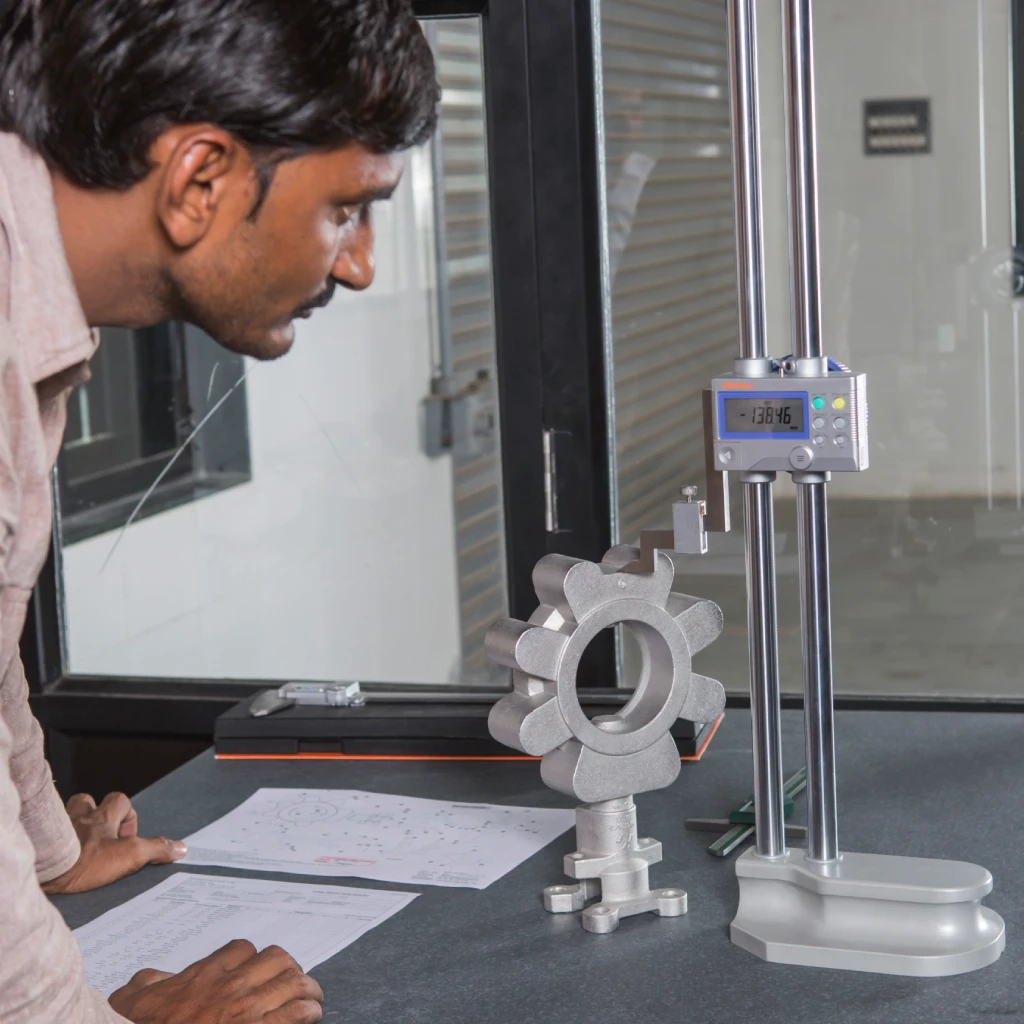

Quality & Testing

Every valve casting undergoes strict quality checks to ensure performance under pressure:

- Dimensional Inspection with calibrated gauges and 3D scanning

- NDT Methods including DP, UT, and radiography

- Hydrostatic & Air Pressure Testing for sealing assurance

- Material Traceability with certified mill test reports

- Documentation provided for QA, heat numbers, and lot-wise identification

Our commitment to zero-defect delivery ensures that your components work perfectly — the first time and every time.

- Serving clients across the globe with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

- Serving clients across the globe with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼

- Serving clients across the globe with precision-engineered components.

- ✼

- Delivering high-tolerance metal parts with complex geometries and repeatable accuracy.

- ✼

- From prototyping to high-volume production, all under one roof.

- ✼